01

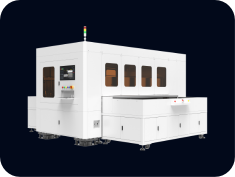

IC Carrier Board Laser Marking Machine

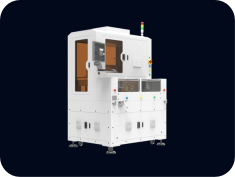

The IC carrier board laser marking machine is specially designed for marking defective indicators such as NG, X, MARK on IC carrier boards.

It integrates a high-performance green laser and a high-pixel imported CCD camera, along with a high-precision XYZ moving module and a flipping platform for automatic positioning.

Defective products can be issued by the MES system or identified by the CCD reading the color of the defective mark.

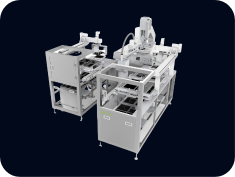

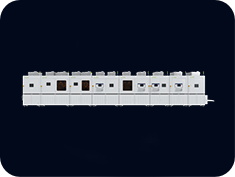

The waste board machine mainly consists of an automatic loading machine, an automatic X-marking machine, and an automatic unloading machine. The automatic loader is responsible for transferring ICS from the ICS trolley to the X-marking workstation of the main machine, where high-precision XYZ module movement performs the X-marking. After marking, the automatic unloader transfers the marked ICS back to the ICS trolley until it is full, thus cycling work, saving manual loading and unloading costs, and improving production efficiency and product quality.

-

-

-

Perform automatic loading and unloading function. Also communicate to AGV to do loading & unloading work.

Perform automatic loading and unloading function. Also communicate to AGV to do loading & unloading work. -

X-marking platform is designed with an automatic flipping function, Achieve double-sided X-marking on ICS in conjunction with vacuum suction positioning

X-marking platform is designed with an automatic flipping function, Achieve double-sided X-marking on ICS in conjunction with vacuum suction positioning -

Automatic Z-axis adjustment design allows for compatibility with different board thicknesses by adjusting the height of the Z-axis.

Automatic Z-axis adjustment design allows for compatibility with different board thicknesses by adjusting the height of the Z-axis. -

Camera and laser coaxial mechanism design enables simultaneous positioning and marking.

Camera and laser coaxial mechanism design enables simultaneous positioning and marking.

-

Laser Parameters

-

Laser Type UV/Green

-

Laser Wavelength 355nm/532nm

-

Laser Output Power 3W/10W

Equipment Performance

-

Processing Capability Single-sided, double-sided X-marking

-

Processing Size Range 50*100-150*250mm(Customizable)

-

Product Processing Thickness 0.1-4.0mm(Customizable)

-

Platform Vacuum Suction Platform

-

XY Axis Movement Speed >25m/min

-

Marking Position Accuracy +0.1mm

-

Marking Repeatability +0.05mm

-

Marking Content X, mark, and other NG indicators

-

Gray Level +20

-

Reading Function Features automatic reading capability,、 supports external barcode or QR code scanning

-

Loading and Unloading Method Suction cup

-

Safety Protection Machine has a protective cover or is enclosed; features emergency stop button and protective sensor devices

-

Positioning Method CCD

-

Automatic Work Platform Precision Linear Modules and Transfer Devices

Main Configuration

-

Operating System WIN7

-

ICS Marking Specific Software IPC

-

Main Control System 3W/10W

-

Auxiliary Control System Import PLC

-

Automatic Loading and Unloading System Suction Cup + Four-axis Robot

Environment Conditions

-

Power Supply Rated Voltage 220V

-

Frequency 50HZ

-

Rated Power 7.5KW

-

Compressed Air 0.6-0.8MPa

-

Environmental Temperature 15-30°

-

Environmental Humidity +0.1mm

-

Equipment Weight 3000KG

-

Operating and Maintenance Requirements Reference Plane Layout Diagram

-

Overall Machine Dimensions Length 2.2m, Width 2m, Height 2.2m (subject to actual specifications)

02

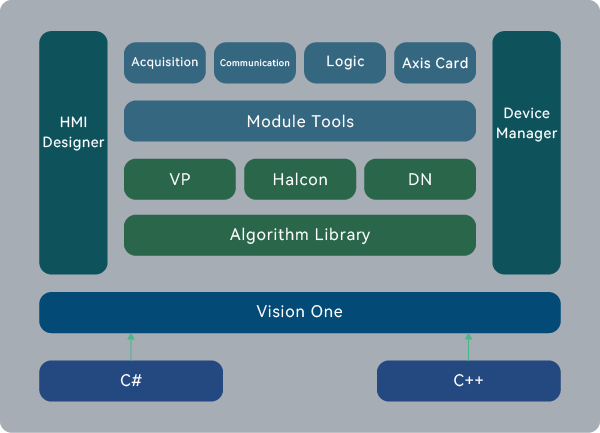

Vision One Visual Development Platform

"Vision One Visual Development Platform is a low-code graphical integrated development environment focused on machine vision and motion control. It integrates VisionPro algorithms and Halcon operators, communication interfaces, human-machine interaction, various acquisition hardware, and dozens of common modules."

Standardization

Standardization- Unified interface style, debugging method, configuration method. Facilitates rapid mass replication deployment and simple maintenance.

Platformization

Platformization-

Integrates various industrial hardware, including core algorithm library modules, HMI interface design, and other modules, allowing for rapid project assembly from pre-configured functions.

Expandability

Expandability-

Supports module expansion and secondary development. Embeddable into user software. Supports C#/VB.net development languages.

Usability

Usability- Graphical programming, drag-and-drop configuration mode, allows free combination of business logic through modules. Avoids complex code-based process creation, lowers development barriers, and enhances efficiency.

Software Framework

Simple and easy to use, effortless operation

- Traditional Development Vision One Visual Development Platform

- Programming Method Code development requires complex design, compile then deploy installation. Graphical programming, building with blocks, what you see is what you get, no need for compilation, runs directly.

- Development Requirements High Low

- Development Cycle Overall longer (estimated 7 days) Short (estimated 2 days)

- Requirement Changes Add function code, recompile, redeploy Direct addition of module functions

- Batch Maintenance Parameters, interface style inconsistencies require professional personnel to adjust details, high maintenance costs. Style, parameters adjustment unified, maintenance personnel can interchangeably replace

Hardware Compatibility

-

Camera:2DBaslerHikvisionDahuaMindVisionAVT3DLMI LaserSSZNKeyence

-

CommunicationMC(Mitsubishi)TCP/IPS7(Siemens)ModbusTCP

(Schneider) Serial Port -

Axis CardGOOGOLTECHZmotion

Consultation Contact Us

-

Phone

0512-66957689

-

Address

No. 11 Tingxin Street, Industrial Park, Suzhou

-

Email

info@dinnar.com

苏公网安备32059002003195号

苏公网安备32059002003195号