- Automatic Intelligent

- Industry solutions

- Core technology

-

Products

- Visual Inspection Equipment

-

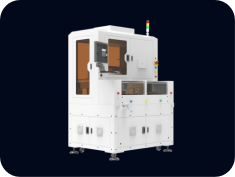

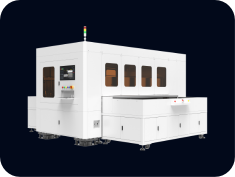

- Laptop Appearance Inspection Device

- Online PCB Visual Inspection Machine

- Mini-LED Glue Defect Inspection Equipment

- Tablet Component Defect Inspection Equipment

- Backlight Panel Size and Contour Detection

- Phone Board 2D Defect AOI

- Mobile Phone Camera Color Deviation Full-Size Inspection Machine

- Mobile Phone Camera Functional Size Inspection Line

- Watch Back Cover Size Detection Equipment

- Monocrystalline Wafer Cutting Blade Defect Detection

- Automatic Defect Detection for Watch Microphones

- Automatic Color Detection for Mobile Phone Buttons

- Battery Composite Film Defect Detection

- Medical Stapler Magazine Inspection

- Medical Saline Bottle Inspection

- Universal Joint Cross Shaft Appearance Defect Detection

- High-Precision Alignment and Lamination of Automotive Windshields and PVD Films

- H1H2 Dedicated Lithium Battery Inspection Equipment

- LCD Screen Measurement

- FPC Flexible Circuit Board Defect Detection

- Universal Platform for Tablet Computer Appearance Defect Detection

- Laptop Appearance Inspection Device

- Vision Measurement Equipment

- Functional Inspection Equipment

-

- Watch Back Cover Glass Translucency Testing Integrated Machine

- Watch Back Cover Glass Illumination Testing Equipment

- Mobile Phone Camera Module Airtightness Testing Integrated Machine

- Watch Back Cover Optical Properties Testing Equipment

- Integrated Machine for Airtightness Testing of Mobile Phone Camera Modules

- Force and Stroke Testing Equipment

- Watch Back Cover Glass Translucency Testing Integrated Machine

- Smart Assembly Equipment

- Intelligent inspection equipment

- Software

- Explore more

Other Industries

-

Detecting Appearance Defects

Scratches, dents, etc. -

Detecting Dimensional Defects

Inconsistencies in size, excessive deviations, etc. -

Detecting Functional Defects

Battery life, wireless connectivity, etc. -

Detecting Safety Performance Defects

Battery overheating, electrical short circuits, etc.

Industry Pain Points

Detection content includes printing errors, content errors, image errors, direction errors, missing prints, surface defects. After high-speed and active photography of the tested object's surface, data is transmitted to a computer for processing to identify defective products. With the rapid development of industries such as OLED, logistics, and furniture, automated machine vision inspection equipment has gradually become an indispensable product in industry use. Low cost, high power, and high accuracy make machine vision technology very widely used.

Solutions

- Medical Industry

- Pump casing

- Aluminum ingot loading and unloading

- Tool production line

-

Medical Saline Bottle Inspection

Defects in industrial medical products can negatively impact the aesthetics, usability, and stability of the products. Therefore, in industrial production applications, defect detection of products is extremely important for the timely identification and control of defective items. This project, based on machine vision inspection methods, overcomes the disadvantages of traditional manual inspection such as low accuracy, low efficiency, high labor intensity, and poor real-time performance.

-

Accuracy: Can achieve virtually zero misses and zero false judgments,thereby improving the customers production capacity

Accuracy: Can achieve virtually zero misses and zero false judgments,thereby improving the customers production capacity -

Meets customer needs:Able to meet customer inspection requirements and production efficiency

Meets customer needs:Able to meet customer inspection requirements and production efficiency -

High efficiency:The inspection tool can detect very small particles and significantly improve production efficiency

High efficiency:The inspection tool can detect very small particles and significantly improve production efficiency

-

Medical Stapler Magazine Inspection

Using machine vision and image processing technology, we can effectively identify whether the bin nail is missing, and quickly and accurately determine whether the product is qualified

-

Meets customer needs:Achieves the precision and speed required by customers

Meets customer needs:Achieves the precision and speed required by customers -

Sequential shooting:A total of 7 shots are taken to detect bright spots on the product surface,accurately determining the presence of staples

Sequential shooting:A total of 7 shots are taken to detect bright spots on the product surface,accurately determining the presence of staples -

Production statistics:Data results and images can be automatically saved and categorized by date and OK/NG results

Production statistics:Data results and images can be automatically saved and categorized by date and OK/NG results -

High precision:Detection accuracy:100%, any product misjudgment leads to scrapping

High precision:Detection accuracy:100%, any product misjudgment leads to scrapping -

High compatibility:Compatible with 9 different product specifications

High compatibility:Compatible with 9 different product specifications -

Detailed inspection:Checks for missing staples at each position

Detailed inspection:Checks for missing staples at each position

-

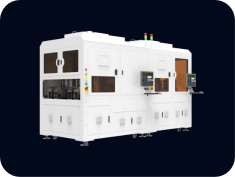

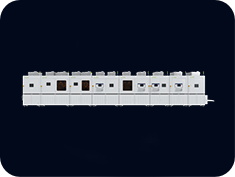

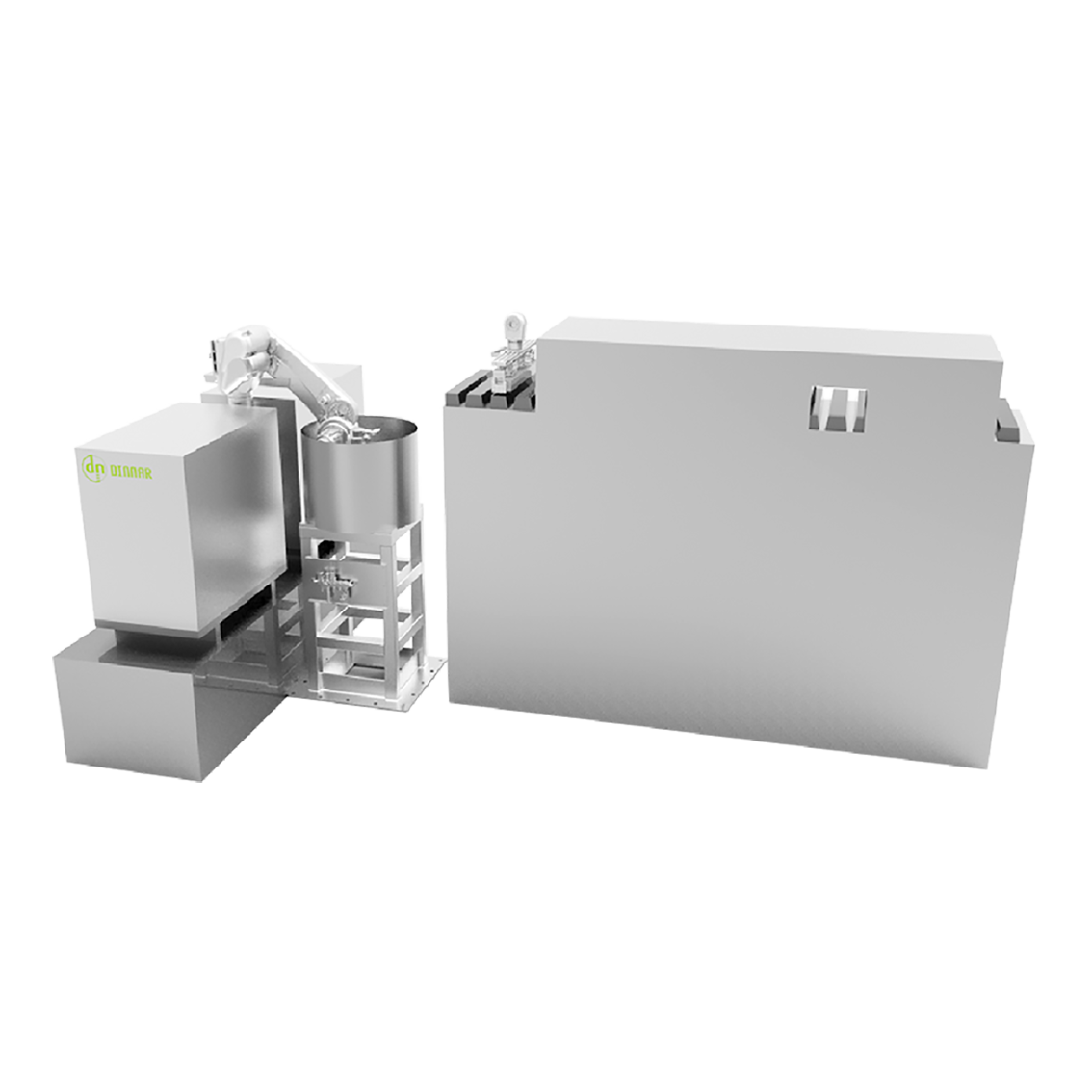

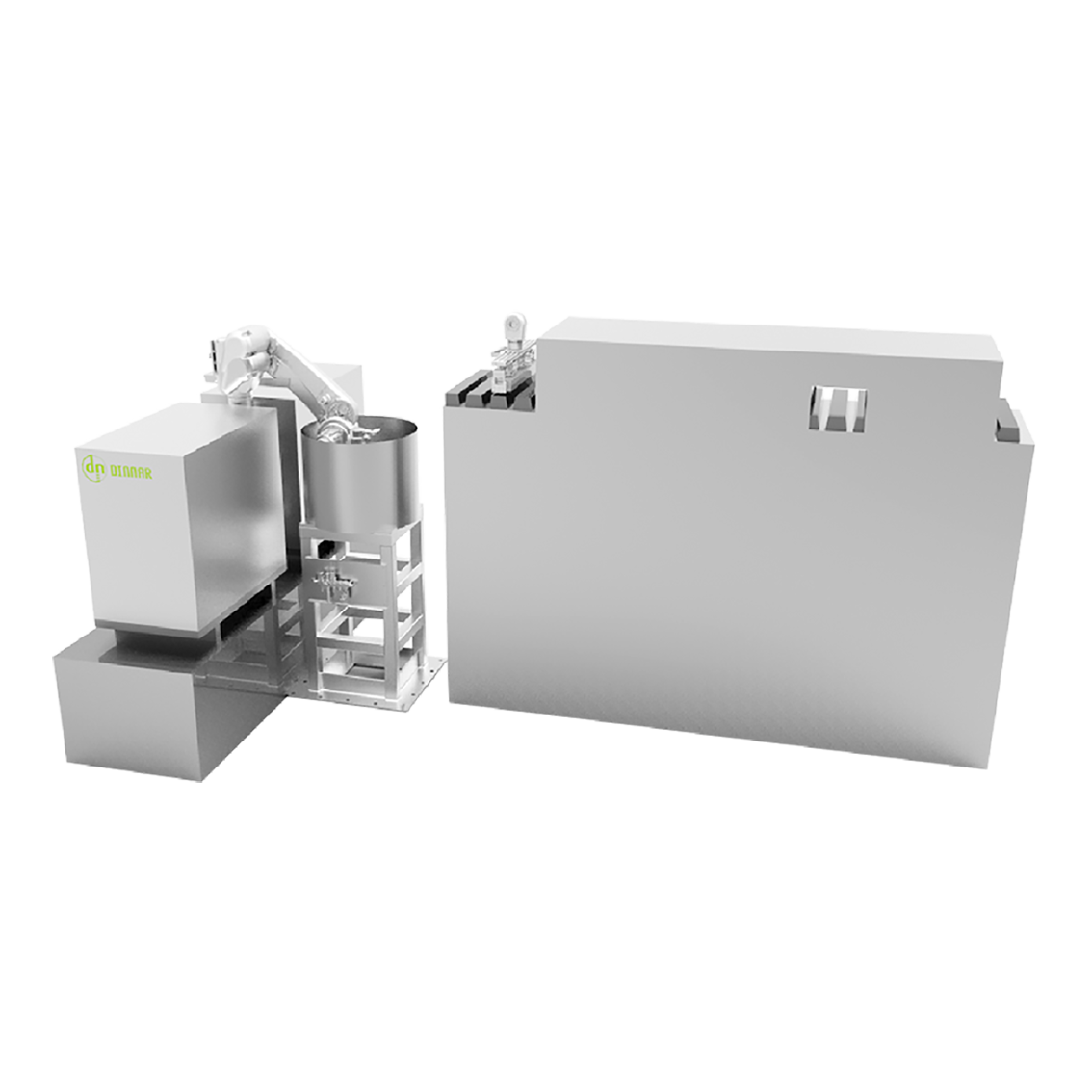

Motor Housing Drilling and Tapping Integrated Machine

Widely used in the 3C industry, automotive and parts, construction machinery, small mold processing, rail transit, aerospace, medical equipment, and other industries for the processing of small plate parts, disc parts, and shell processing.

-

Modularity: Modular structure, strong interchangeability, easy to disassemble and assemble.

Modularity: Modular structure, strong interchangeability, easy to disassemble and assemble. -

High compatibility: Compatible with 4 types of product production, short CT (within 30S).

High compatibility: Compatible with 4 types of product production, short CT (within 30S). -

High precision: One-time positioning, multi-angle hole drilling and tapping, high precision.

High precision: One-time positioning, multi-angle hole drilling and tapping, high precision. -

Single machine operation mode: Turntable structure, multi-station integrated processing, first in the industry to create a single machine operation mode.

Single machine operation mode: Turntable structure, multi-station integrated processing, first in the industry to create a single machine operation mode.

-

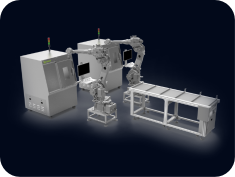

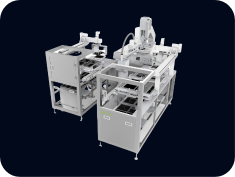

Robot Loading and Unloading

Developed for the frequent and labor-intensive characteristics of loading and unloading work. The company has developed this system and has added a vision control unit to the traditional robot loading and unloading system, which is used to automatically identify the position of the workpiece. This significantly reduces the precision requirements for the position of the workpiece during robot loading and unloading, thereby reducing the hardware costs for customers. The vision control unit consists of vision sensors, controllers, etc.

-

High precision: Camera positioning, accurate grabbing. Repeated grabbing precision of 0.2mm.

High precision: Camera positioning, accurate grabbing. Repeated grabbing precision of 0.2mm. -

Product protection: Reduces labor intensity, protects products (if there are surface protection requirements).

Product protection: Reduces labor intensity, protects products (if there are surface protection requirements). -

High safety: Heavy material handling (8KG), high safety factor.

High safety: Heavy material handling (8KG), high safety factor. -

High efficiency: The robot's handling CT is short, and efficiency is high.

High efficiency: The robot's handling CT is short, and efficiency is high.

-

Monocrystalline Wafer Cutting Blade Defect Detection

This equipment is mainly used for high-precision product tracking and detection, achieving the detection of notches over 1um on circular blades, with a detection accuracy of depth 1um and width 5um. The equipment is equipped with functions such as barcode scanning recognition and sample cleaning before detection, which realizes product tracking and positioning, avoiding the impact of dirt, foreign objects, etc., on the accuracy of detection.The equipment is equipped with adjustable fixtures, enabling the detection of products ranging from 40-130mm. This device provides a good solution for multi-model, high-precision detection products in the 3C industry, daily necessities industry, and others.

-

Automatically cleans the product tooling before each detection,to avoid secondary contamination

Automatically cleans the product tooling before each detection,to avoid secondary contamination -

Complies with ergonomic design,easy for personnel to operate, improving work efficiency

Complies with ergonomic design,easy for personnel to operate, improving work efficiency -

Uses the Findline tool for precise measurement,capable of detecting defects up to 8um

Uses the Findline tool for precise measurement,capable of detecting defects up to 8um

Related Products

-

Medical Saline Bottle Inspection

Machine vision inspection methods overcome the disadvantages of traditional manual inspection such as low accuracy, low efficiency, high labor intensity, and poor real-time performance. -

Medical Stapler Magazine Inspection

Using machine vision and image processing technology, effectively identify whether nails are missing in the warehouse, quickly and accurately judge whether the product is qualified. -

Motor Housing Drilling and Tapping Integrated Machine

Widely used in industries such as 3C, automotive and components, construction machinery, small mold processing, rail transport, aerospace, medical devices, etc. -

Robot Loading and Unloading

In traditional systems, a vision control unit has been newly added, greatly reducing the accuracy requirements for the position of workpieces during robot loading and unloading. -

Monocrystalline Wafer Cutting Blade Defect Detection

Using high-resolution cameras and image processing technology to quickly and accurately detect surface and internal defects in monocrystalline cutting pieces.

Consultation Contact Us

-

Phone

0512-66957689

-

Address

No. 11 Tingxin Street, Industrial Park, Suzhou

-

Email

info@dinnar.com

Suzhou Dinnar Automation Technology Company All rights reserved | 苏公网安备32059002003195号

苏公网安备32059002003195号

苏公网安备32059002003195号

苏公网安备32059002003195号