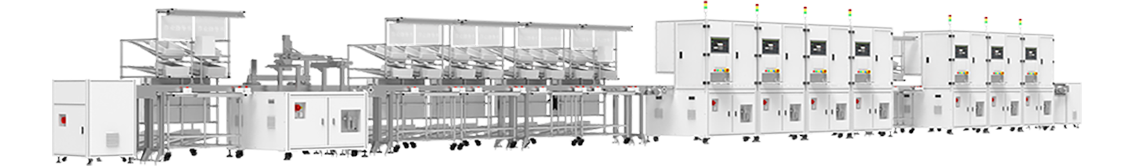

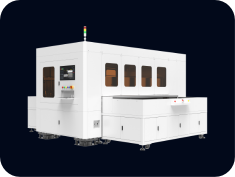

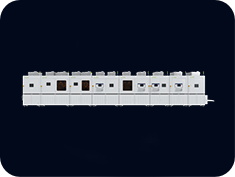

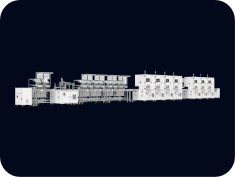

Automotive Door Lock Assembly Line

Application in Automotive Door Lock Assembly Production:

This assembly line incorporates a MES system and integrates numerous processes such as riveting, oil spraying, screw fastening, and laser marking, equipped with inspection capabilities to upload data to the MES system. This ensures that each product can be traced back to its specific manufacturing processes and dimensional parameters. The production line is flexible; it can be disassembled and recombined to accommodate different product models and meet various manufacturing requirements. Compared to traditional manual production lines, it minimizes the risk of large-scale product scrapping, controlling quality at every stage and reducing the defect rate.

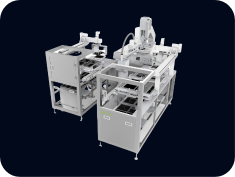

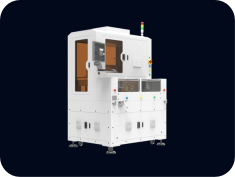

Line process

Riveting, oil spraying, screw fastening, laser marking.Inspection precision.

Rivet height±0.02mmHigh production output

UPH300Compatibility

Compatible with left front, left back, right front, and right backApplicable products

Car Door Lock AssemblyDetection System

DN software platform

Application Case

Automotive Door Lock Assembly Line

Application in Automotive Door Lock Assembly Production:

This assembly line incorporates a MES system and integrates numerous processes such as riveting, oil spraying, screw fastening, and laser marking, with added inspection capabilities that upload data to the MES system. This ensures that each product can be traced back to its specific manufacturing processes and dimensional parameters. The production line is flexible; it can be disassembled and recombined to accommodate different product models and meet various manufacturing requirements. Compared to traditional manual production lines, it minimizes the risk of mass rejection, controlling quality at every stage and reducing the defect rate.

Product application case: Automotive Door Lock Assembly Line

Consultation Contact Us

-

Phone

0512-66957689

-

Address

No. 11 Tingxin Street, Industrial Park, Suzhou

-

Email

info@dinnar.com

苏公网安备32059002003195号

苏公网安备32059002003195号