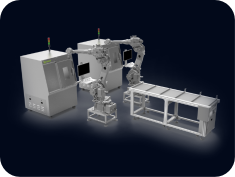

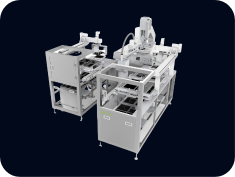

Intelligent Roller Assembly Line

Currently, in mouse manufacturing enterprises, the roller assembly process has always been manually operated, with product quality relying on manual labor. To address this, an intelligent automatic roller assembly line has been developed, achieving fully automated production of roller assembly, significantly ensuring product quality stability while greatly alleviating labor issues for enterprises.

1. Achieves automatic feeding of all parts, automatic assembly of rotors, weak magnetic stators, O-rings, brackets, foam, etc.

2. Implements automatic gluing, oiling, automatic testing, and automatic offloading of finished products.

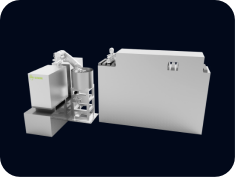

Assembly parts

Rotor, weak magnetic stator, O-ring,bracket, foam, magnet, inner ring, etc.Function items

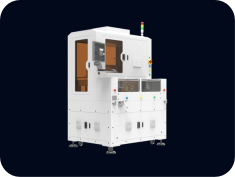

Gluing, oilingTesting functions

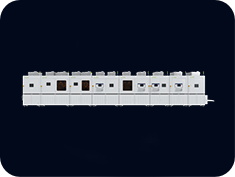

Jump test, speed test, flat swing test, etc.Equipment footprint

Dimensions (L×W×H):12m×3m×2mApplicable products

Mouse rollerDetection method

OnlineCT

12s

Application Case

Intelligent Roller Assembly Line

Currently, in mouse manufacturing enterprises, the roller assembly process has always been manually operated, with product quality relying on manual labor. To address this, an intelligent automatic roller assembly line has been developed, achieving fully automated production of roller assembly, significantly ensuring product quality stability while greatly alleviating labor issues for enterprises.

1. Achieves automatic feeding of all parts, automatic assembly of rotors, weak magnetic stators, O-rings, brackets, foam, etc.

2. Implements automatic gluing, oiling, automatic testing, and automatic offloading of finished products.

Product application case:Mouse roller production line.

Consultation Contact Us

-

Phone

0512-66957689

-

Address

No. 11 Tingxin Street, Industrial Park, Suzhou

-

Email

info@dinnar.com

苏公网安备32059002003195号

苏公网安备32059002003195号