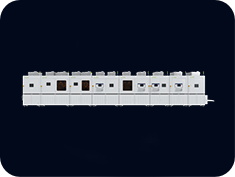

Phone Board 2D Defect AOI

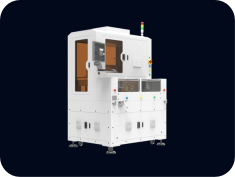

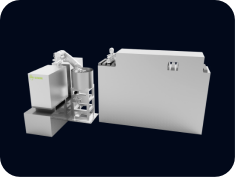

Intelligent visual dimension measurement system, developed by Dinnar for defect detection needs such as electronic industry mobile phone components. It is mainly used for dimension detection of metal parts that require defect detection. This system uses visual imaging detection technology to calculate measurement needs such as multiple components, foreign objects, insufficient tin, short circuits, excess glue, insufficient glue, glue offset, and glue overflow

Detection type

Multiple components, foreign objects, insufficient tin, short circuits, excess glue, insufficient glue, glue offset, glue overflowHighest precision

0.01mmDetection speed

18s/PCSMaximum detection size

50*100mmApplicable products

Mobile phone componentsDetection method

Online/offlineCamera

Industrial cameraDetection system

DN software platform

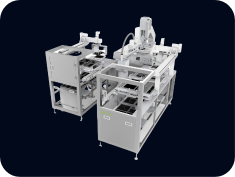

Application Case

Phone Board 2D defect AOI

Intelligent visual dimension measurement system, developed by Dinnar for defect detection needs such as electronic industry mobile phone components. It is mainly used for dimension detection of metal parts that require defect detection. This system uses visual imaging detection technology to calculate measurement needs such as multiple components, foreign objects, insufficient tin, short circuits, excess glue, insufficient glue, glue offset, and glue overflow

Product application case:Mobile phone component production line

Consultation Contact Us

-

Phone

0512-66957689

-

Address

No. 11 Tingxin Street, Industrial Park, Suzhou

-

Email

info@dinnar.com

苏公网安备32059002003195号

苏公网安备32059002003195号